Acoustic monitoring of bridges

Artificial intelligence, technology and the ability to remotely monitor structures are some of the most modern and useful innovations to enter the construction industry in recent times.

This is particularly true in the field of structural and geotechnical monitoring. To check and maintain the long-term structural health and safety of assets, this field can utilise several highly effective methods with broad applicability, immediate operability and reliable efficiency.

Acoustic monitoring of bridges is one of these innovations, aimed at accurately detecting any problems with structural cables in a non-invasive and efficient way.

Our internationally experienced expert, Nicolas Cortes, explains how this technology can be used to maintain the structural safety of bridge projects; what the benefits are and how it works.

Could you please describe the technology behind the acoustic structural monitoring of cable structures? How does it work specifically?

The technology uses piezoelectric sensors designed to detect the noise (vibration in material) generated by the failure of a structural cable wire as it releases the energy stored during its tensionning. Sound travels within the infrastructure (similar in frequency range, but very different from a microphone that is used to record sounds travelling in air).

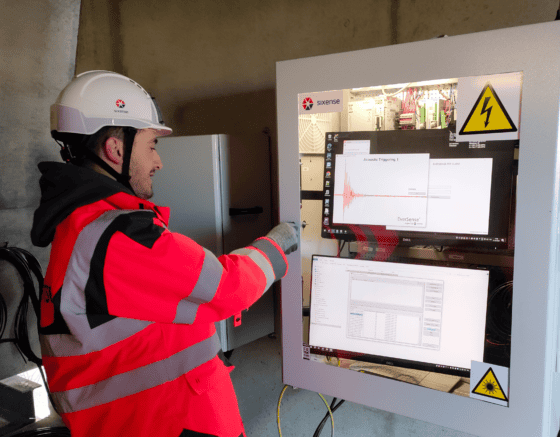

SIXENSE’s system is designed to record every sound produced within the structure. These recordings are made by each individual sensor with a highly accurate synchornisation (µs). An advanced triggering condition strategy ensures that only the sounds of interest are recorded. These short-time recordings are called “events”.

Drawing on over 20 years of experience, we have developed an Artificial Intelligence (AI)-based filtering algorithm that pre-processes the events and retains only those that match the acoustic signatures of a wire break. In the final stage, an expert analyst confirms whether the event is an actual wire break. We use proprietary software with a localisation tool to analyse the events and identify where the event occurred.

The technology applies to the monitoring of all types of structural cables used in civil engineering (stay cables, post-tensioning cables, pre-tensioning cables, suspension cables, anchor cables, etc.).

Why is acoustic structural monitoring important / mandatory for bridges?

Acoustic monitoring is not mandatory. It is usually used in cases where corrosion or fatigue is suspected or found during inspections, and the structural cables (e.g. stay cables or post-tensioning cables used to increase the load-bearing capacity of a bridge) are at risk.

What are the risks to be considered by public authorities/beneficiaries of these structures – if they do not implement acoustic structural monitoring on bridges?

Partial or total structural failure of the bridge is the main risk. Cables are designed to increase the load-bearing capacity of bridges, so failure of one or more cables can put the structure at risk. As a result, traffic restrictions or repair work may be necessary.

What are the main benefits of implementing acoustic structural monitoring on bridges? Please comment on the expected outcomes and results.

Acoustic monitoring makes it possible to follow the progressive degradation of structural cables, to prioritize maintenance on specific parts of the bridge, and in some cases decide whether the bridge is still safe to use (or within certain traffic load restrictions). It is a very valuable source of information for engineering departements to take into consideration.

Acoustic monitoring is usually complementary to other NDT solutions in order to provide a complete picture of some key structural elements. It is the only technology available that has the sensitivity to detect and continuously monitor the event of a single wire break and to identify the structural element involved. No other technique can currently provide this level of sensitivity to damage, on a continuous monitoring basis.

What is the main way of working with this type of structural monitoring? How can it be used/adapated locally, in bridge projects?

Ageing cabled-bridges, with a serious suspicion of corrosion or fatigue should be targeted. It may be possible to instrument only specific cables or a local section where specific ageing has been observed.This partial approach can optimise the cost of a system that could be expensive and not necessarily usefull if applied without prior consideration.

This monitoring can provide confidence in the rate of ageing (if few events are observed) or allow time to organise cable replacement (if significant damage is observed).

To discuss your monitoring requirements, pleace Contact Us.