Sixense’s Cyljet solution enables in-situ dimensional verification of jet-grouted injected columns during construction. This includes:

- Quick checking of column dimensions

- Optimisation of material usage

- Optimisation of site costs and schedules

An exclusive solution developed by Sixense

The benefits of Cyljet

- Significant optimisation of operational costs:

Cyljet enables injection parameters to be calibrated to the highest-possible level of precision

- A robust and proven method:

Cyljet removes the requirement to excavate around columns in order to check the injection quality

- A quick solution:

Fast survey times and rapid availability of results (less than 48 hours after completion of measurements)

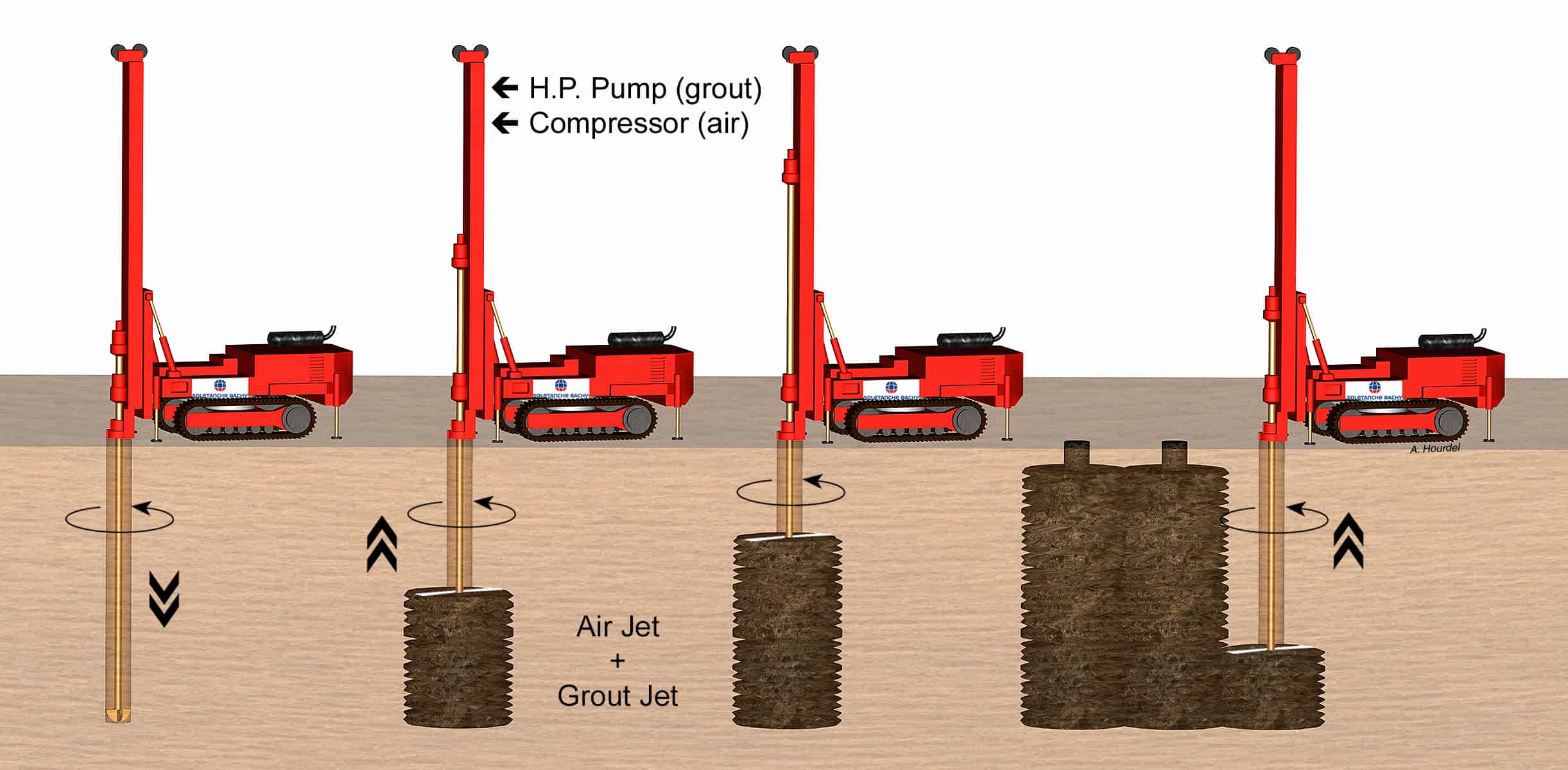

The principle of Cyljet

Sixense’s Cyljet solution enables in-situ dimensional verification of injected columns during construction. The solution is based on the Electric Cylinder method, and provides 3D investigation around the full circumference of the column.

A multicore cable with evenly spaced electrodes is installed at the centre of the column to record and process the potential differences generated by an induced electric current to produce a 3D image of the injected column.

This solution can equally be used to validate a test plot, as well as provide continual checking of injection quality as work progresses.